Mining Technology Solutions

Toward a Safer, Smarter, and Cleaner Mining Industry

Helping the mining industry to evolve rapidly toward a more sustainable future. By investing in a smarter workforce, resilient supply chain, and cleaner operations.

Overcoming the Biggest Challenges of Mining Industry

Higher CAPEX / OPEX

- Long Engineering Cycles, Delayed Handoff to Ops

- Delayed and Over-budget Projects Deliveries

- Higher Production Downtime and Inspection Costs

Weakened Value Chain and Productivity

- Unbalanced Supply and Demand Planning

- Impaired Forecasts and Tracking from Pit to Port

- Poor Overall Equipment Effectiveness (OEE)

Constrained Workforce

- Weakened Collaboration with Remote Operations

- Impeded Workforce Efficiency without Data Insights

- Lack of Situational Awareness and Safety Procedures

Resetting Mining Industry Toward a Sustainable Future

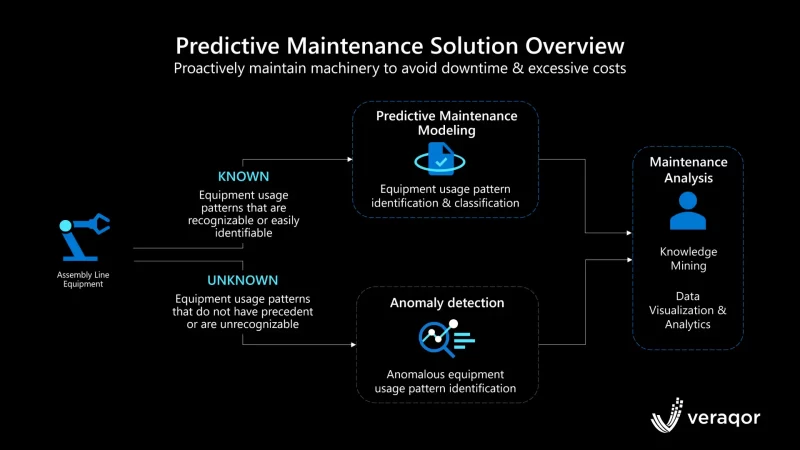

Predictive Maintenance

Key Benefits

Enhanced mining equipment reliability

Minimized operational downtime and inspection costs

Optimized maintenance scheduling

Prevents unforeseen equipment failures

Technical Capabilities

Real-Time Mining Analytics

Monitor and manage multiple mines and overall equipment efficiency (OEE) with the assistance of the Internet of Things (IoT) and sensor data.

Mining Processes Management

Execute flexible mining and extraction processes and collaborate seamlessly in an integrated environment.

Predictive Maintenance Trends

Predictive maintenance for mobile equipment ranks sixth globally in terms of the overall degree to which mines have invested in it.

When properly implemented, predictive maintenance maximizes profits by minimizing the risk of losses due to system failure.

The global predictive maintenance market, which was valued at 4.5 billion US dollars in 2020, is projected to reach the size of 64.3 billion US dollars by 2030.

Transitioning from preventive to predictive maintenance can enhance a mining company’s overall equipment effectiveness (OEE) from 50-75%.

Predictive maintenance can reduce maintenance planning time in mining and metal operations by 20-50% and overall maintenance costs as well.

A typical mining operation spends 35-50 percent of its annual operations budget merely on asset maintenance and repairs.

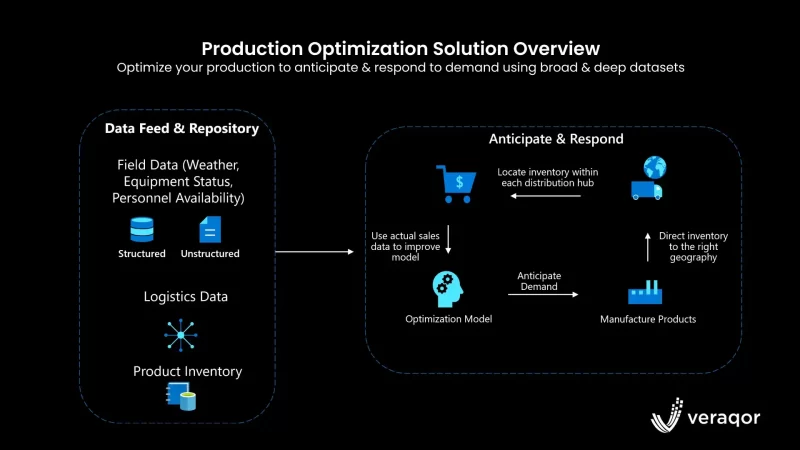

Optimizing Production and Scheduling

The mining industry is a dynamic sector with intricate operations and production. With escalating costs for maintenance, transport, machinery, workforce, and other resources; shifting environmental regulations; fluctuating market demand; managing resources such as water and energy; ensuring safe procedures; enhancing sustainability initiatives; minimizing waste generation; improving process efficiency and throughput optimization, it’s crucial for the industry to utilize data-driven solutions.

Key Benefits

Effectively manage open-pit and underground operations

Integrated cross-functional data streams

Optimized mineral extraction

Improved profitability

Technical Capabilities

Optimizing Mining Operations with AI and Data

Data analysis through AI allows operators to make more informed decisions on when to commence an excavation or kick-start an operation that may significantly impact profits – by analyzing various factors such as geological conditions, equipment status, or personnel availability. AI can also be used to assess risk before work starts by conducting predictive maintenance on machinery or predicting potential failures based on historical incidents.

Optimizing Production and Scheduling Trends

Optimizing operations and scheduling in the mining industry can lead to a 2-5% increase in extraction efficiency.

Over half (58%) of mining companies use advanced analytics for production optimization.

The market for production optimization solutions in the mining industry is projected to reach approximately $8.5 billion by the end of 2023.

Digital technologies can reduce operating costs by up to 20% in open-pit operations and up to 30% in underground operations.

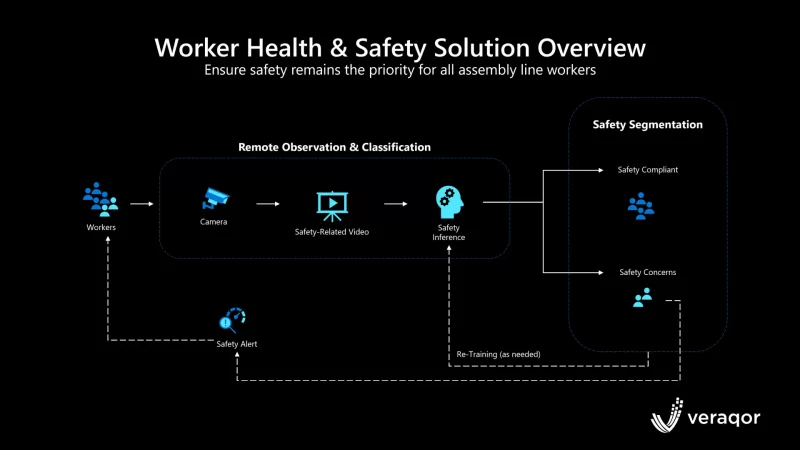

Employee Health & Safety

Utilize the potency of IoT sensors and AI to gain end-to-end mining process flow analytics to supervise safety standards and violations in real time. Employ predictive analytics across the mine and processing sites to optimize workflows and minimize waste. AI ensures the avoidance of production downtime due to safety violations and personnel injury on the mining site.

Key Benefits

Enhanced worker satisfaction & productivity

Ensure regulatory compliance such as OSHA & MSHA

Technical Capabilities

Real-time OEE for Safety

Track and oversee multiple mining sites and overall equipment effectiveness (OEE) with the help of the Internet of Things (IoT) and sensor data to ensure optimal operations and miners’ safety.

Spatial Analysis

Using computer vision, spatial analysis infers worker safety across the mining site using video feed from the IoT-enabled edge.

ML-based Disaster Prevention

Continually monitor safety levels in a mine or sense potentially hazardous situations such as rock falls or flooding in order to mitigate potential disasters.

Employee Health & Safety Trends

According to the CDC, in all the US industries combined, the fatality rate in the mining sector is 7.25 times higher.

The global market for digital solutions in mining is projected to reach $8.7 billion by 2025, growing at a CAGR of 8.7% from 2020.

46% of mining companies already use or plan to use wearable technology in the workplace.

Companies that prioritize worker health and safety outperform their peers in terms of financial performance, with a 20% higher return on investment and a 2.2% higher return on assets.

Digital technologies can reduce accidents by up to 20% and improve productivity by up to 15%.

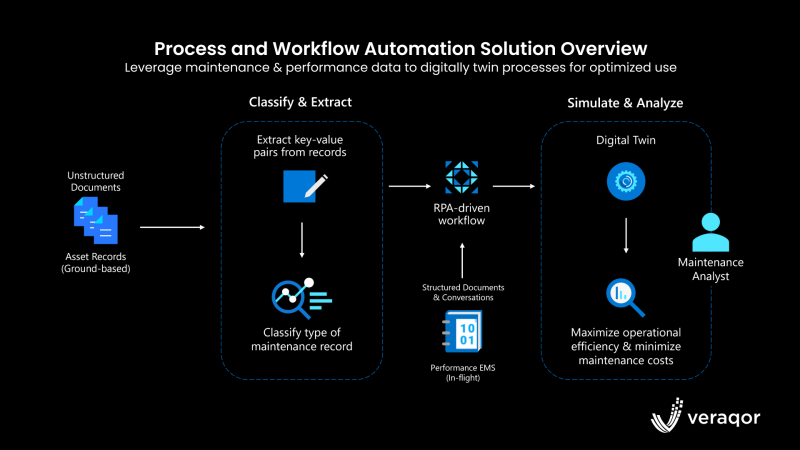

Process and Workflow Automation

Leverage critical data for insightful & forward-thinking business decisions through AI. Utilize data and AI to digitally mirror intricate mining systems in near real-time and improve efficiency.

Key Benefits

Boosted productivity

Prompt and actionable information

Economically efficient operations

Technical Capability

Form Recognizer

Convert extensive volumes of records into useful data, digitize unstructured documents, including handwritten notes, and surpass traditional OCR to categorize document types and extract field names and values.

Process and Workflow Automation Trends

55% of mining companies have adopted process automation technologies.

Automating workflows can reduce mining costs by up to 15% and increase production by up to 25%.

The process automation market in mining is projected to reach $15.2B by 2025.

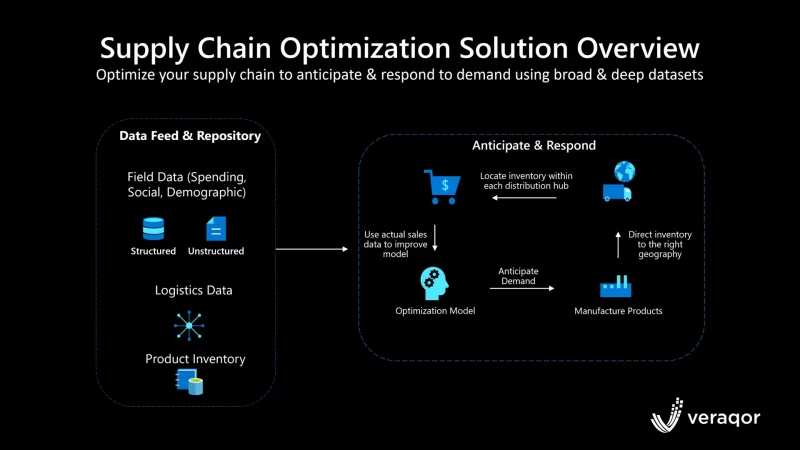

Supply Chain & Logistics Optimization

Delivering a smart supply chain to anticipate market demands and detect changes in supply and demand. Intelligent connected supply chain to launch a range of highly personalized add-on services and gain insights about market needs based on trends, signals, and behavior patterns. Drive new growth with modern data estate, analytics, and AI by delivering exceptional operational experiences.

Key Benefits

Improved order fulfillment and promising

Efficient raw material sourcing and logistics

Sustainable load optimization

Enhanced logistics (tracking & traceability)

Better supply chain visibility

Reduced transportation costs

Technical Capabilities

AI/ML-based Inventory Management

Boost business resilience by quickly responding to disruptions and intelligently selecting alternatives for supply shortages.

Intelligent & Connected Demand Planning

Respond to changing market demand with machine learning, connected processes, and increased visibility across sales and operations planning (S&OP), forecasting, supply, replenishment, and inventory functions.

Real-time Orders and Shipments Tracking

Optimize logistics processes with visibility into minerals in transit, notify stakeholders about deviations, and monitor fulfillment.

Supply Chain & Logistics Optimization Trends

The global mining market has shown significant growth, expanding from $2022.6 billion in 2022 to $2145.15 billion in 2023 at a CAGR of 6.1%.

The mining industry spends an average of 10-15% of its operating costs on logistics.

The global mining market is expected to grow at a CAGR of 6.7% from 2023 to 2027.

Optimizing logistics can reduce mining costs by up to 5%.

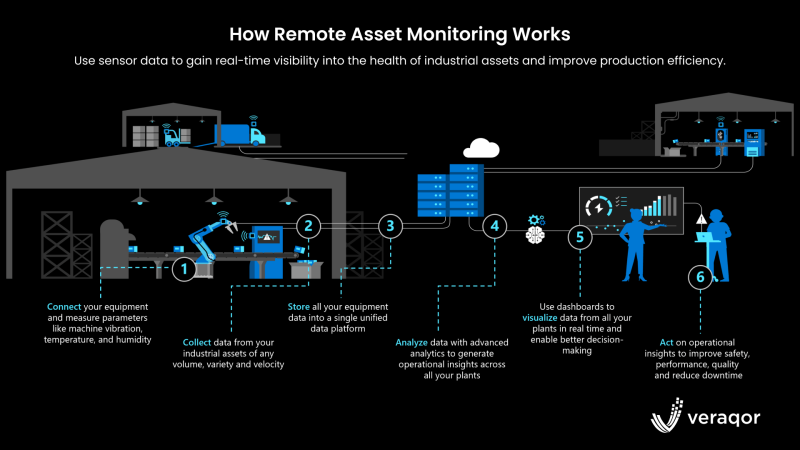

Real-time Asset Tracking

Harness the power of data and AI to boost the efficiency and reliability of your assets-tracking system. Gain real-time insights into assets utilization, movement, and behavior using geolocation, RFID, and IoT sensors. We simplify the process of accessing key metrics and critical information to ensure secure and optimized operation.

Key Benefits

Real-time location tracking for optimized delivery schedules minimized inventory loss and theft

Mining equipment monitoring through real-time critical indicators such as equipment temperatures, vibrations, etc., to better predict machine downtime

IoT-enabled mine management to monitor mine parameters such as humidity, temperature, and pressure to prevent inventory damages

Technical Capability

Real-time Assets and Shipments Tracking

Enhance logistics processes with visibility into assets in transit, notify stakeholders about deviations, and monitor fulfillment while keeping an eye on equipment and inventories to prevent any loss of stock and machinery.

Real-time Asset Tracking Trends

The use of Internet of Things (IoT), artificial intelligence (AI), and big data analytics can reduce logistical costs in the mining industry by up to 15%.

IoT-connected equipment can help to reduce equipment downtime by up to 20%.

Optimizing supply chain and logistics processes can improve operational efficiency in the mining industry by up to 25%.

AI-powered maintenance scheduling can help to reduce maintenance costs by up to 30%.

Multi-Faceted Expertise for Industry-Wide Coverage

- Reservoir Planning

- Well Planning

- Reservoir / Well Modeling

- Geological Information Systems

- Well Design & Simulation

- Drilling Optimization

- Drilling Optimization

- Asset Management

- Flow Simulation

- Reservoir Engineering

- Production Forecasting

- Operations Management

- Remote Monitoring

- Supply Chain Management

- Pipeline Management

- Subcontract Operations Management

- Tracking & Traceability

- Inventory Management

- Project Based Monitoring

- Real-time Process Optimization

- Crude Blending Optimization

- Feedstock Logistics & Crude Quality

- Demand Forecasting

- Yield Accounting and Margins

- Oil Movement & Storage

- Operational Control Over Network

- Real-time Access to Inventory levels

- Tracking and Development

- Predictive Models to Manage Demand

Marketing

- Customer Contract Management

- Service Level Agreements

- Human Resource Management

- Loyalty Programs

- Operational Insights and Collaboration

- Forecourt Management

Installation Services & Assistance

Industry Scenarios

Generating Business Value Across Industries

Enterprise solutions that provide real-time, actionable insights.

This solution allows COOs to look after their equipment effectively, use sensor data and analytics, closely monitor their equipment performance in real-time, and predict when maintenance is needed. The cloud can fast-process vast volumes of data to extract real-time insights, leading to cost-effective and efficient operations.

This solution helps companies assess their capacity, requirements, and demand and build accurate reservoir models, eventually leading to optimized production and better recovery rates. These models function by incorporating data gathered from multiple sources, such as seismic imaging, historical production data, sensors, and more.

This solution enables mining companies to dive deep into their data and gain insights regarding their supply chains, allowing them to identify inefficiencies and anomalies and capitalize on opportunities for process optimization. Using the cloud, real-time collaboration, and sharing data among stakeholders make supply chain operations more effective, resulting in better yield.

Through the cloud's real-time processing, organizations can monitor any external environmental factors, such as air and water quality, enabling them to be aware of any potentially harmful impacts. This also helps companies ensure their workforce's safety, avoiding any hazardous operations that may result in a catastrophe.

This solution helps CXOs gather and analyze data from various sources. The seismic imaging data, geological surveys, historical product data, and other sensor data can be processed through cloud analytics tools to help mining exploration companies to be more specific with their exploration and production planning, reducing risks and improving overall efficiency, leading to ideal results.

See How Organizations Are Innovating

Pioneering Knowledge Availability, Accelerating Collaboration, and Cost Reduction by 40%

Situation

As part of the company’s strategic vision, the IT division was tackling a significant challenge. They aimed to transform and enhance collaborative efforts by undertaking the project of consolidating and centralizing its mail services.

Solution

A comprehensive solution was sought that not only fulfilled the immediate need for an economical, centralized email system but also laid robust groundwork for future growth. This solution offered cutting-edge email and collaboration services at a competitive price point. Also, it ensured the necessary security and control were in place to meet all requirements.

Impact

The strategic changes have yielded significant results for the company. By streamlining procedures, the company was able to cut costs by 40%, enhancing financial efficiency. The user experience was improved, fostering positive engagement and boosting productivity. Operations became smoother and more efficient, while existing investments were smartly reused to maximize resources, thus promoting sustainability.

Empowering Employees Worldwide, Improving Productivity & Informed Decision-Making by Pioneering a Novel Digital Strategy

Situation

Solution

Impact

Transformative Power of Digital Solutions Cuts Costs and Triples Collaboration for 11,000+ Workers on Remote Sites

Situation

Solution

To address these issues, the company chose to upgrade its communication system to a more efficient and advanced platform. This solution provided the company’s 11,000 workers with a simple, consistent way to set up and conduct meetings, whether they were in conference rooms, at their desktops, or using mobile devices.

Impact

The impact of this strategic change was substantial. It enhanced safety measures, improved operational efficiency, and fostered increased collaboration among employees. Moreover, the company managed to cut its travel budget by 50%, tripled the use of audio/video meetings, and reduced cellular bills by 20%. This demonstrated the transformative power of smart digital solutions when effectively implemented.

Revolutionizing Geo-Metallurgical Analysis with Swift and Powerful Solutions

Situation

Solution

A new Integrated Geo-metallurgical Simulator (IGS) solution was developed as a response to this challenge. This entailed manually implementing a basic multithreading engine to achieve multicore scalability and reduce block-processing times to 100 milliseconds. Further advancements were made by upgrading to an advanced development environment and framework, which offered new parallel processing features that significantly decreased simulation times.

Impact

The solution resulted in accelerated geo-metallurgical analysis and improved environmental impact analysis. The processing performance was maximized swiftly and easily, introducing powerful new features. More importantly, it opened doors for new consulting services, demonstrating the transformative power of smart digital solutions when effectively implemented.